Friction stir welding

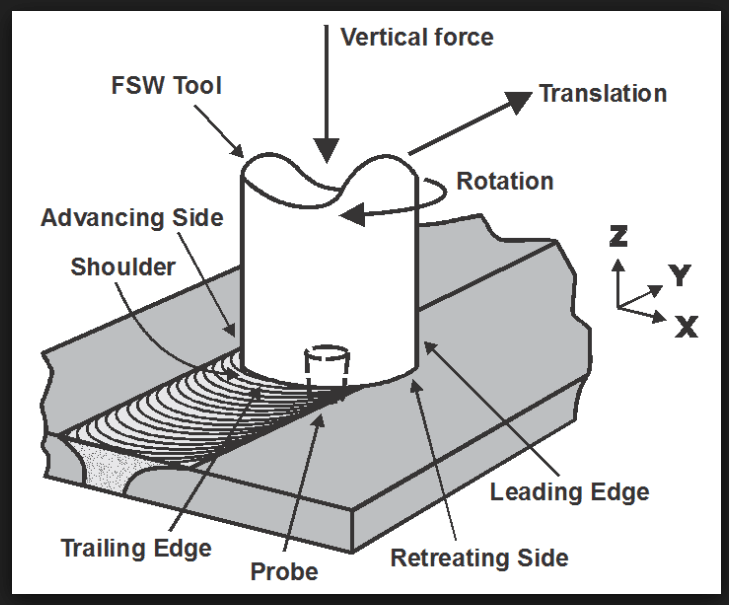

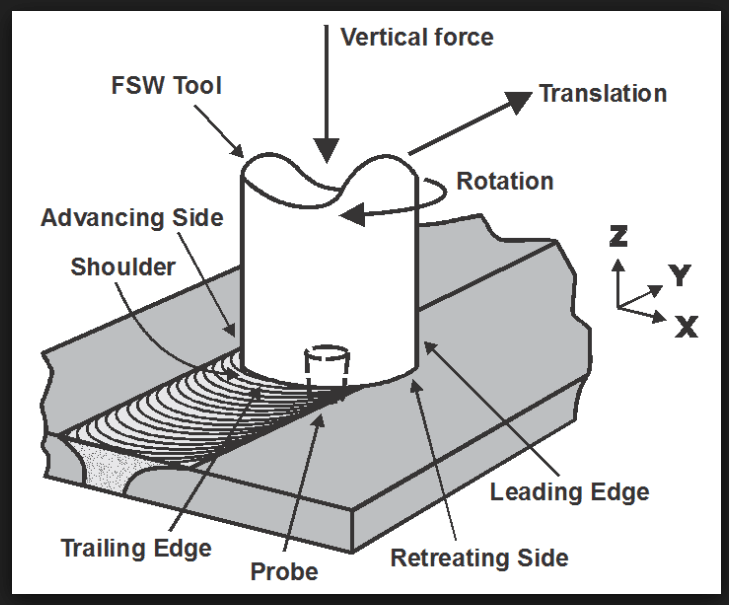

Friction stir welding is a solid welding method that achieves welding. Under the action of pressure, under the action of constant or increasing pressure and torque, the relative motion between the welding contact end faces generates frictional heat and deformation heat in the friction surface and its vicinity, so that the temperature in the vicinity thereof rises to The temperature range close to but generally lower than the melting point, the deformation resistance of the material is reduced, the plasticity is increased, the oxide film of the interface is broken, and under the action of the upset pressure, the plastic deformation and flow accompanying the material, the molecular diffusion and recrystallization through the interface A solid state welding method that achieves welding.

Friction welding usually consists of the following four steps:

1. Mechanical energy is converted into heat energy;

2. Plastic deformation of the material;

3. Forging pressure under thermoplastic;

4. Intermolecular diffusion recrystallization.

The biggest difference between the friction stir welding phase and the traditional welding is that the temperature at which the metal to be welded reaches the temperature rise does not reach its melting point during the whole welding process, that is, the metal is a forging solid phase connection realized in a thermoplastic state.

Compared with traditional fusion welding, friction welding has high quality of welded joints - it can reach the strength of weld strength and base material, high welding efficiency, stable quality, good consistency, and can realize welding of dissimilar materials.

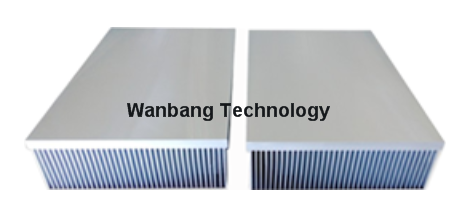

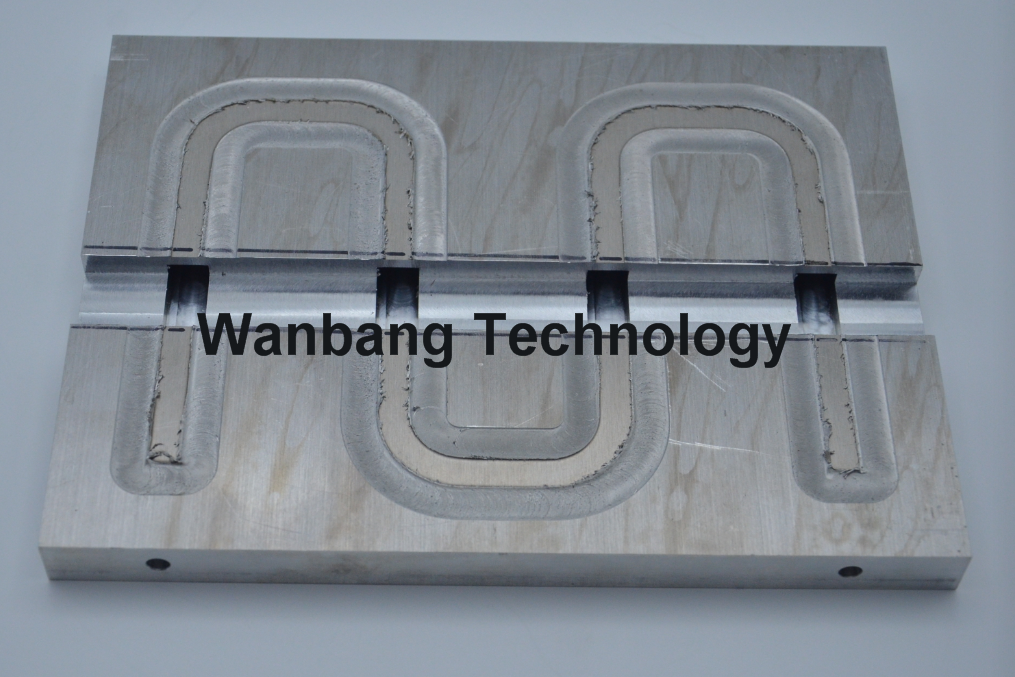

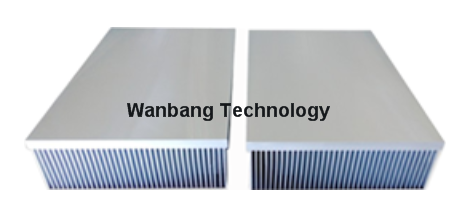

The friction radiator can solve the bottleneck of high-multi-wide profile technology by using friction welding. It can realize ultra-wide structure and high-density profile by splicing two or more profiles, and the mold development cost is low, the cycle is short, and the stability is high. Wanbang relies on the R&D team for a long time. The accumulated data, with rich production technology and technical strength, provide users with more solutions.

One: two or more profiles

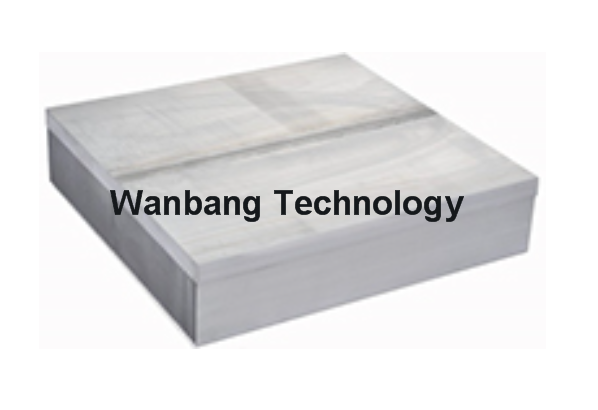

Two: splicing multiple heat dissipation modules into one larger module through the process of friction stir welding

Three: integrated machining, integrated performance after machining

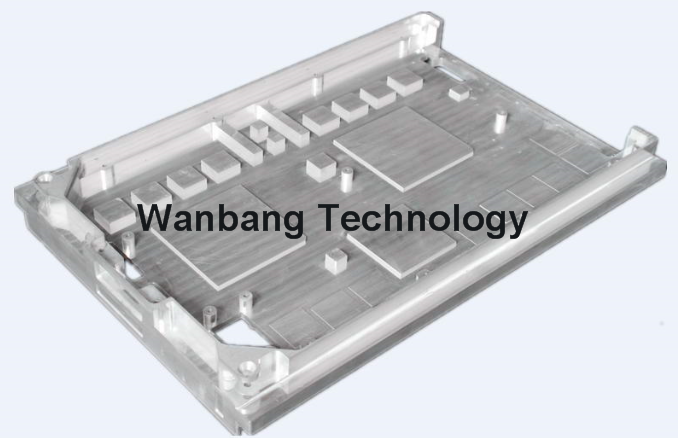

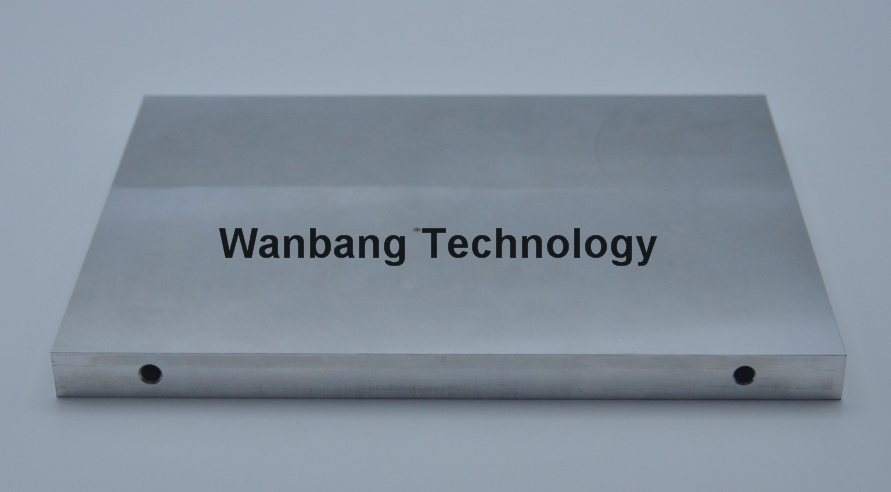

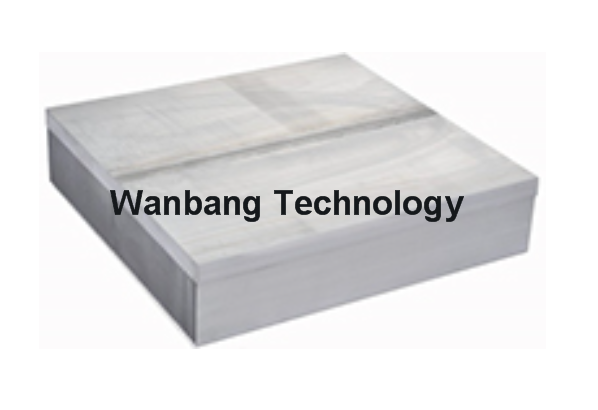

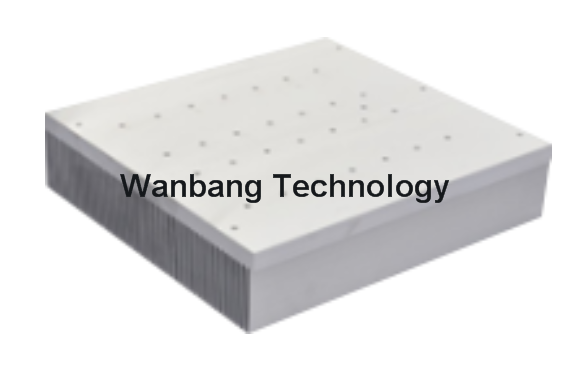

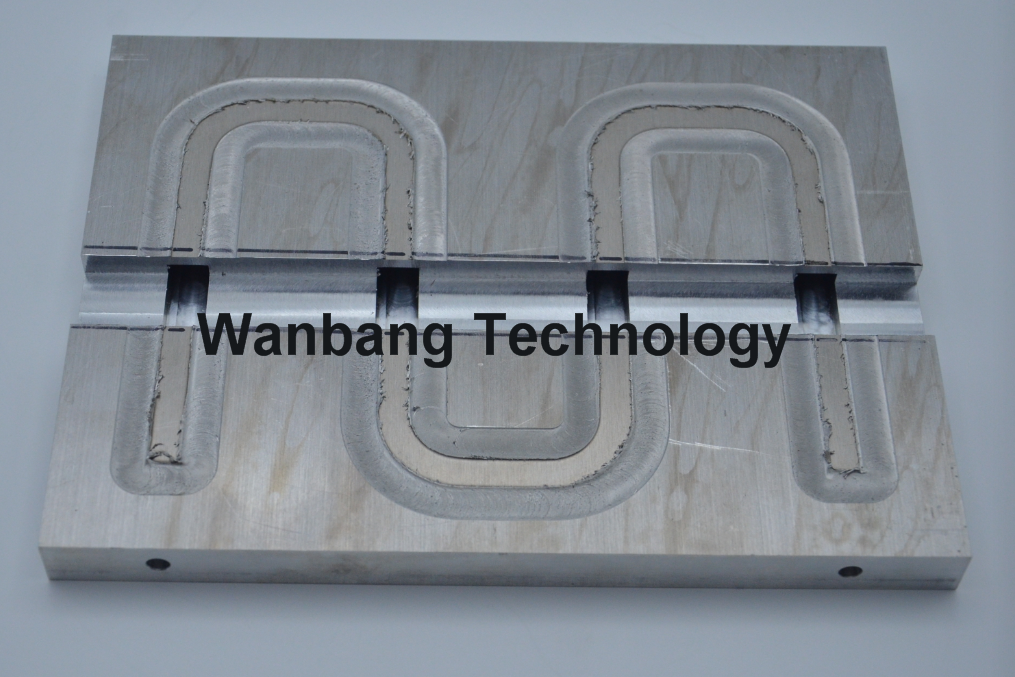

Water cooled board

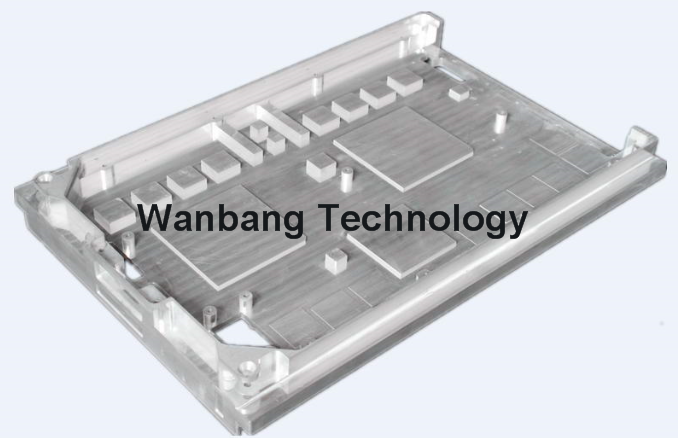

New energy electric vehicle water-cooled motor housing

Die-casting friction stir welding

Widely used in aviation, aerospace, shipbuilding, rail transportation, electric power, electronics, weapons manufacturing and engineering, energy, construction, electrical and other industries